IntriPlex and Forge Battery enter supply agreement to boost lithium-ion battery cells with ultra-precision manufacturing and Atomic Armor™ technology. This supply agreement marks a significant milestone in both companies’ growth trajectories.

IntriPlex and Forge Battery enter supply agreement to boost lithium-ion battery cells with ultra-precision manufacturing and Atomic Armor™ technology. This supply agreement marks a significant milestone in both companies’ growth trajectories.

Discover how IntriPlex Technologies is advancing US lithium-ion battery manufacturing with its new cylindrical lid assembly capability. Whether for electric vehicles or energy storage systems, IntriPlex delivers high-quality, precision-engineered components to meet the evolving needs of the battery industry.

A precision partnership —we delve into a collaboration that defines precision, innovation, and excellence. This dynamic alliance is reshaping the landscape of metal stamping, pushing boundaries, and setting new standards for excellence.

The announcement is part of a long-term strategic initiative from IntriPlex to lead with global industrial excellence in the battery industry. Mr. Galyen’s appointment further strengthens IntriPlex’s commitment to driving innovation and excellence in energy storage solutions.

Join IntriPlex, the catalyst for cutting-edge EV technology. Elevate your battery production with our precision engineering, global agility, and commitment to seamless scalability. Powering the future of mobility, one innovation at a time.

There are lots of players in the pursuit for making electric vehicle batteries and their components. The problem? Cell manufacturers are facing trouble meeting production commitments. That’s why IntriPlex has a different approach.

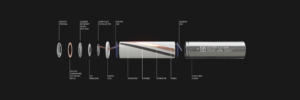

Discover how lithium-ion batteries work, from the role of lithium ions to the interaction between anode and cathode. Explore the six key components that store and release energy, and understand why these batteries have transformed energy storage.

From understanding the nuanced process to exploring key materials, design considerations, and the factors influencing quality, this article is your gateway to the heart of precision engineering.

Benchmark spoke to Donald J. MacCrindle, Business Development Director at IntriPlex Technologies, about the critical role lithium-ion battery cell components will play in scaling up battery production to meet electric vehicle and energy storage demand.