SOLUTION-ORIENTED

MANUFACTURING

CAPABILITIES

SOLUTION-ORIENTED

MANUFACTURING CAPABILITIES

Manufacturing Capabilities & Services

Our proven engineering and manufacturing capabilities enable us to produce top-tier products across a spectrum of industries. Working hand-in-hand with our customers, our global team of engineers leverages technical expertise, advanced manufacturing resources, and cutting-edge testing to bring innovative solutions to market. Our approach to projects is to curate our services to meet the needs of each customer, and build together through a combination of design, engineering, and strategy. It’s never too early to get started with us, from concept through manufacturing we bring end-to-end product development services under one roof. IntriPlex offers premium-quality service and custom solutions for the industries that matter most—yours.

Our Services

PRECISION METAL STAMPING & FORMING

Our precision metal stamping and forming technology is a fast and cost-effective solution for manufacturing large quantities of complex products. We can mass produce intricate metal components with very consistent results. It is well known that high-speed stamping is among the most efficient manufacturing processes, but not every part can be stamped. The core of our innovation is finding ways to stamp the traditionally “un-stampable.”

TOOL & DIE DESIGN & DEVELOPMENT

For over 35 years, IntriPlex has been designing and building custom tool and dies for leading OEM and top tier manufacturers in the data storage, medical, telecommunications, automotive industries, and more.

While many stamping manufacturers outsource tool and die design and production, our tool room is in-house, and our IntriPlex tool designers are also tool and die makers with production precision forming experience. Our engineering teams use sophisticated 3D CAD modeling design software enabling us to design and modify progressive dies on screen with product simulations prior to actual production.

Our Tool & Die Teams collaborate closely with our Research & Development and Product Engineering teams to understand the component design and performance requirements. We offer expert recommendations on part designs, material selections, and maximizing material space with efficient part layouts. We aim for the most effective design to minimize tooling cost and maximize manufacturing efficiency.

ENGINEERING DESIGN & SUPPORT

Everything we do at IntriPlex is based on meeting and exceeding the expectations of our customers. We want to make things happen, and we know the only way to do that is to take the leap and get working. We champion the creative spirit and work as determined and as hard as our customer teams to get things done.

Our technical team of PhD-holders and engineers employs state-of-the-art engineering, modeling, testing and inspection techniques to monitor products throughout the development and production phases. In addition, our world class Innovation Center is available for collaboration and the development of complex parts. Many of our customers find it beneficial to consult us in the conceptualizing phase, enabling us to optimize tooling, manufacturing processes, and value chain management steps and services.

PROTOTYPING

Precision and rapid prototyping can make all the difference in helping our customers stay ahead of the market. That’s why, as a technology partner, IntriPlex is highly committed to research and development and prototyping capabilities. We are always ready to accept new challenges and offer full collaboration with our customers.

Through our design for manufacturing process, our engineers ensure our customers’ parts are manufactured as efficiently as possible. We don’t waste our customer’s time with guesswork. Our customers save time and money and gain peace of mind with our upfront design for manufacturing reviews that trim costs, improve quality, and simplify the transition to production.

Our ability to take our customer’s ideas and turn them into producible, high quality, high volume, economical solutions is what makes us unique. From pre-prototype to production we are with you all the way.

SECONDARY OPERATIONS

Precision metal stamping is our specialty, and to meet our end goal of superior part quality and excellent adherence to part specification, we utilize a wide assortment of in-house processes to achieve fully finished metal stamped parts that seamlessly integrate into our customers’ products. Our secondary operations enhance the parts’ performance and improve part appearance all while maintaining the parts’ shape.

At IntriPlex, we utilize a wide assortment of in-house processes to remove burrs or conduct surface modification to the metal parts. Our secondary operations include:

✓ Mechanical deburr

✓ Chemical deburr

✓ Electrochemical deburr

✓ Electropolishing

✓ Etching

IntriPlex’s secondary operations result in exceptionally smooth, uniform parts and add significant advantages to our customer’s parts.

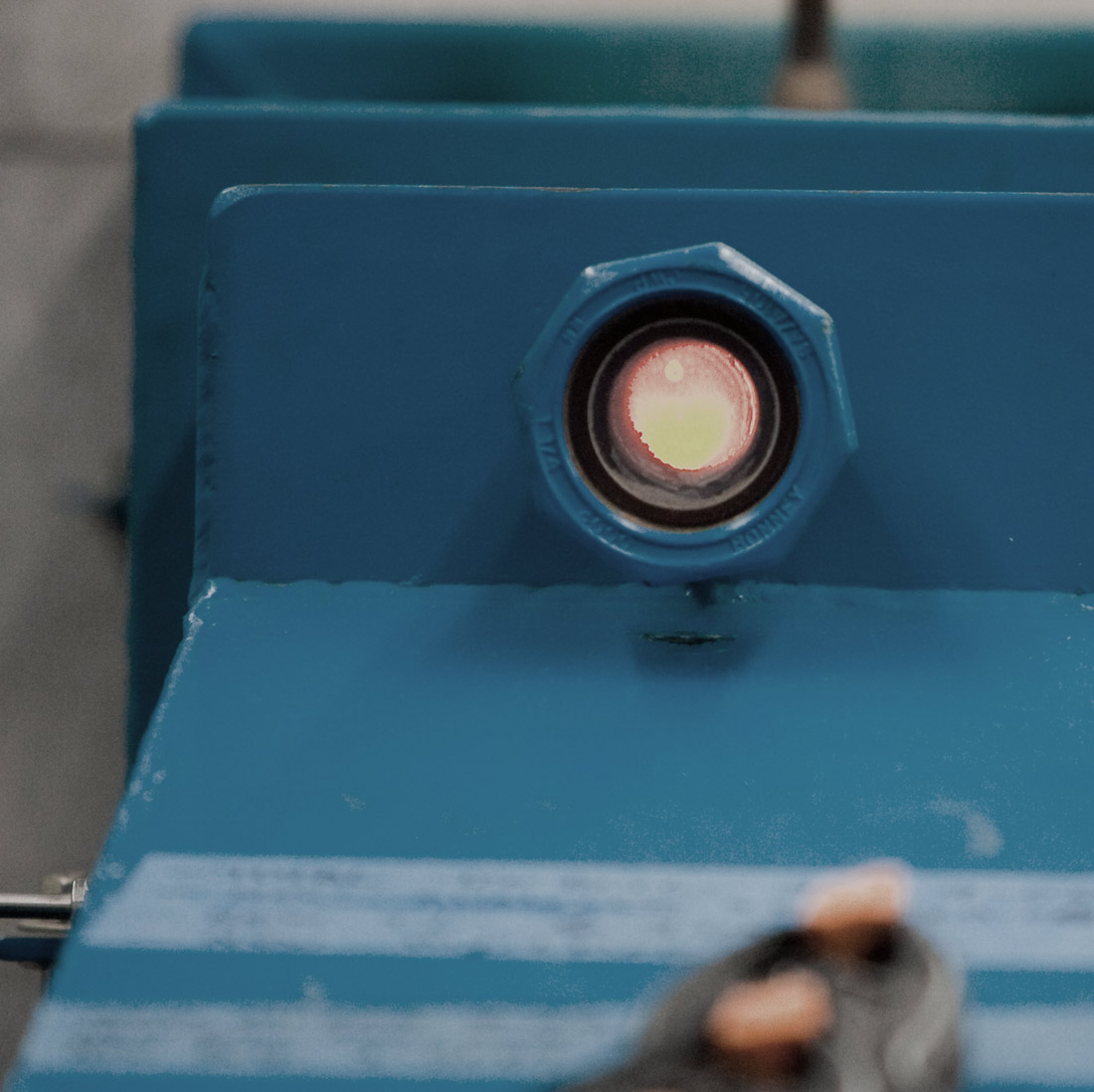

THERMAL PROCESSING

Companies turn to IntriPlex for heat treatment of their small precision parts. It is our objective to bring value to our customers in unique ways by understanding and responding to their challenges through becoming a direct extension of their team. Our proprietary heat treatment techniques process parts in a manner that helps reduce or eliminate distortion. Our furnaces employ nitrogen and hydrogen gases as protective atmospheres, resulting in clean, bright parts. These processes are ideal for high production volumes and enable us to provide expedient, cost effective heat treatment. All production is monitored per product-specific process control plans, using statistical process control and data systems.

Our distinction lies not just in our manufacturing capabilities but in the artistry of our process. Precision delivers the end product, but true excellence resides in the meticulous orchestration of every step along the way.

ADVANCED CLEANING

Cleaning metal stampings is critical to the parts’ finish and purpose, as any contaminants could affect the part’s function. IntriPlex excels at precision cleaning by leveraging our advanced technology and environmentally friendly processes. We follow the most stringent product quality testing standards for both particulate and chemical cleanliness.

Utilizing multiple ultra-pure aqueous cleaning lines located in Class 10K clean rooms with Class 100 final process environments, we manage cleaning to the highest level of compliance. Our standards include 18 Mohm DI water and ultra-pure plumbing along with multi-frequency ultrasonic treatment and Ultra clean optimized part handling. The result is that IntriPlex produces the cleanest parts available, a requirement for data storage and medical clients.

IntriPlex has installed dedicated testing labs staffed with chemical engineers and full-time lab assistants to provide production quality support. These tests and processes include:

✓ Liquid Particle Count (LPC)

✓ Ion Chromatography (IC)

✓ Liquid Particle Analysis (LPA)

✓ Atomic Absorption Spectroscopy

✓ Passivation Testing

✓ Scanning Electron Microscopy (SEM)

✓ Energy-Dispersive X-Ray Spectroscopy (EDS)

✓ Tape-Particle Analysis (TPA)

✓ Ultrasonic cleaning

We offer guidance on cleaning and finishing options that will be most effective for our customer’s stamped part specifications and industry standards.

MATERIAL CONVERSION

There are more innovative materials than ever before, and here at IntriPlex we use our deep understanding of materials and part performance needs to develop materials in unique ways to improve the function of our customer’s product.

Custom material conversion is any process that modifies the original material. Some of the most common material conversion techniques we employ involve the receipt of tape, liner and adhesive products from key suppliers, followed by the transfer of these tapes and adhesives to other components or materials. For example, IntriPlex creates dampening products by accurately transferring viscoelastic adhesives to stamped metal constraining layers. IntriPlex is an approved converter of materials from 3M, JDC and others.

GENTLE DRYING TECHNIQUES

The drying method employed following cleaning is important in preserving the part’s integrity. IntriPlex uses various drying processes depending on part size, part fragility and cleanliness requirements. One process uses HEPA filtered hot dry air introduced to flat baskets of parts which are oriented toward the air stream by a robot such that part-to-part impingement is minimized. This prevents damage to fragile parts as well as the generation of particles.

QUALITY INSPECTION

Our customers want nothing less than top quality and neither do we. Quality in production doesn’t happen with just one step, so we apply the strictest quality control standards to every part of the manufacturing process from receipt of material through production.

IntriPlex develops material specifications that are more stringent than industry standards to ensure the best part quality and part performance. Incoming inspection confirms that supplier certifications conform to these specifications, and performs critical parameter audit testing, including in some cases, in-house tensile testing of materials.

In-process and final inspection utilizes IntriPlex-developed metrology, including 25 nm resolution contact gages, interferometer-based profile measurements and camera and laser CMMs. Visual inspection is done at multiple stages per customer and internal AQL levels. Critical parameters are tracked using an SQL database with electronic alarm notifications to production and engineering staff for any aberration in the manufacturing process.

Our quality system is based upon the foundations of ISO 9001, Lean certified manufacturing practices, and our quality-focused team.

ADVANCED ASSEMBLY TECHNIQUES

No two projects are alike, and that’s why IntriPlex’s battery cell component design and assembly services are tailored to our customer’s needs. We offer a wide range of value-added services for our customers who require the manufacturing and delivery of complete battery lid assemblies. Our assembly capabilities include:

✓ Specialized micro-handling automation

✓ Laser and resistance welding

✓ Plating and hardening

✓ Extensive cleaning processes

✓ Gluing and coating

✓ Intelligent vision inspection system

✓ Product testing

✓ Full lid assembly

The battery market is rapidly picking up pace, and IntriPlex is a strategic and forward-looking partner working closely with customers on the design, manufacturing, and assembly of battery cell lid components. Our design and customer-centric mindset means we are always looking for ways to improve the efficiency and reliability of our processes while reducing manufacturing costs.

CUSTOM PACKAGING

IntriPlex custom packaging services is designed to meet customer needs and ensures that components arrive uncompromised and completely ready to be integrated into their products. Solutions have included parts in heat sealed double cleanroom bags in clamshell trays with bubble wrap, parts stacked in custom tubes for integration into customer automation, tape and reel, and vacuum packing.

The primary difference between IntriPlex and other manufacturers is our mastery of the manufacturing method: flexible, customizable, and advanced manufacturing capabilities, plus a willingness to stretch the limits and explore “what’s possible” versus “what’s simple.” Tough challenges are the norm not the exception.