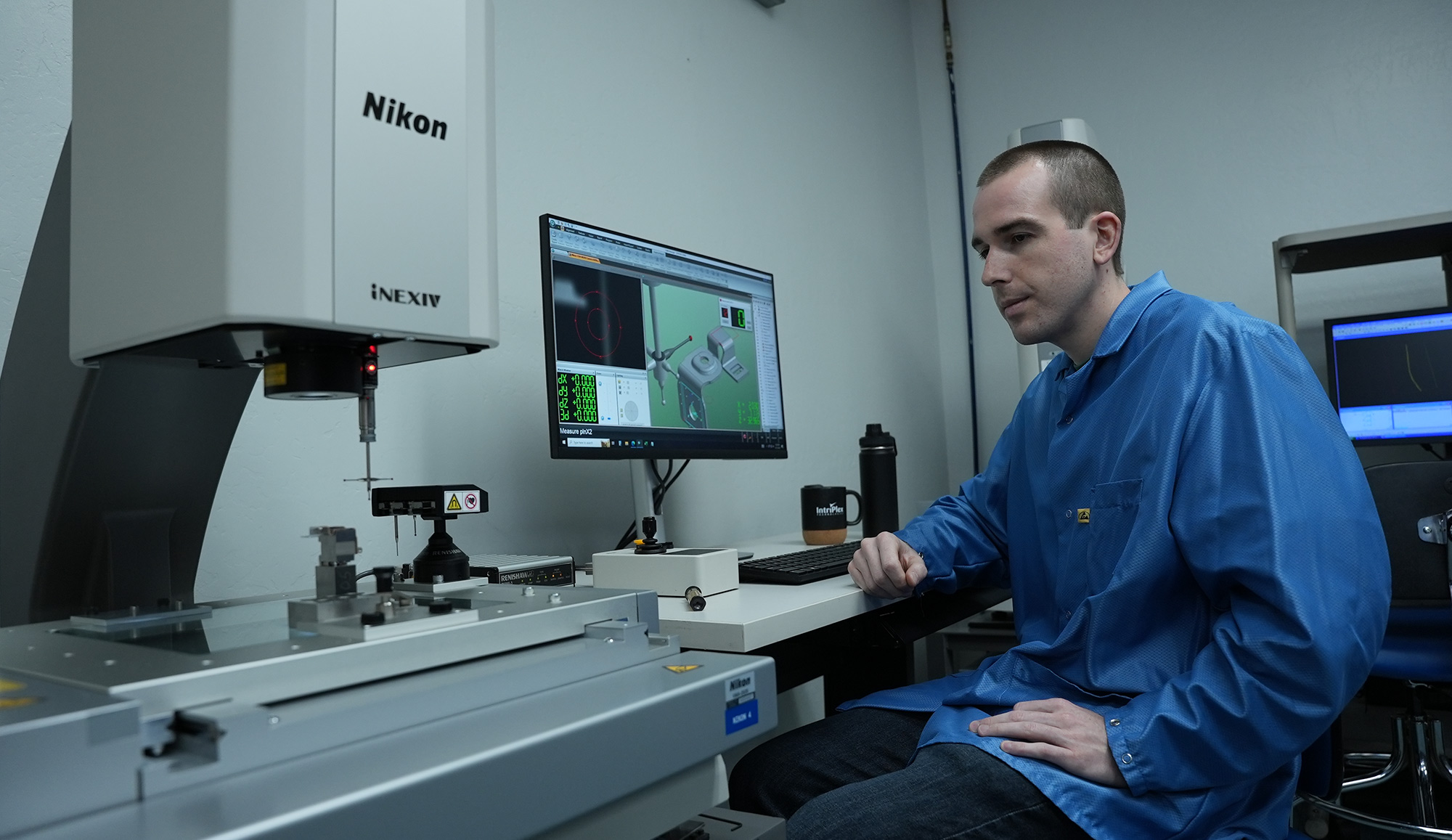

Precision Metal Stamping with Nikon’s iNEXIV VMA-2520 System

Precision is non-negotiable in metal stamping. Even the slightest deviation from specifications can lead to product defects, increased production costs, and compromised safety. At IntriPlex, we consistently pushed the boundaries of innovation to deliver reliably precise products for our customers. Our unwavering commitment to excellence, is underscored by continuous investments in cutting-edge technologies, keeping us at the forefront of a competitive market. A key catalyst behind our success lies in our dedication to quality assurance, a commitment that has been further reinforced by our recent integration of Nikon’s iNEXIV VMA-2520 video measuring system.

Nikon’s iNEXIV Video Measuring System

Nikon’s iNEXIV VMA-2520 video measuring system emerged as the ideal solution for us in leveling up our quality assurance capabilities. This innovative technology combines advanced imaging capabilities with powerful measurement algorithms, allowing for high-precision inspection of intricate metal components. The iNEXIV VMA-2520 system is equipped with a high-resolution camera and intelligent software that can accurately measure complex geometries, ensuring that each stamped part meets the specified tolerances.

Key Features of Nikon’s iNEXIV VMA-2520 System

High-Resolution Imaging: The iNEXIV VMA-2520 system employs high-quality optics and advanced imaging sensors to capture detailed images of metal stamped parts. This ensures that even the smallest features are accurately represented.

Multi-Sensor Capability: IntriPlex benefits from the versatility of the iNEXIV system, which supports various sensors for different measurement tasks. Whether it’s optical measurements, touch probes, or laser scanning, the system adapts to the specific needs of each metal stamped component.

Automated Measurement Processes: Automation is a key driver of efficiency. The iNEXIV system automates the measurement process, reducing human error and increasing throughput. This not only improves quality control but also enhances overall production efficiency.

Intuitive Software Interface: The user-friendly interface of the iNEXIV system’s software allows IntriPlex technicians to easily program and execute measurements. This ensures a seamless integration into the company’s existing quality control workflow.

Benefits for IntriPlex and Our Customers:

The integration of Nikon’s iNEXIV video measuring system has yielded several benefits for IntriPlex and, by extension, our customers:

1. Enhanced Product Quality: The precision offered by the iNEXIV system ensures that every metal stamped component meets or exceeds the specified tolerances, resulting in higher product quality.

2. Faster Time-to-Market: The automated nature of the iNEXIV system accelerates the quality assurance process, reducing the time required for inspection and speeding up overall production timelines.

3. Cost Savings: By minimizing the risk of defects and rework, IntriPlex has experienced cost savings associated with improved production efficiency and reduced material waste.

4. Customer Confidence: Clients of IntriPlex can be confident in the reliability and consistency of the stamped components they receive, knowing that they have undergone rigorous quality control using cutting-edge technology.

IntriPlex’s adoption of Nikon’s iNEXIV video measuring system exemplifies our company’s commitment to delivering precision-engineered metal stamped components. As the metal stamping industry continues to evolve, the integration of advanced technologies like the iNEXIV system positions IntriPlex as a leader in quality assurance, our customers receive products that meet the highest standards of accuracy and reliability.